Mind Technology

Creative Solutions for Your Industry

Mind Technology

Creative Solutions for Your Industry

Select your language

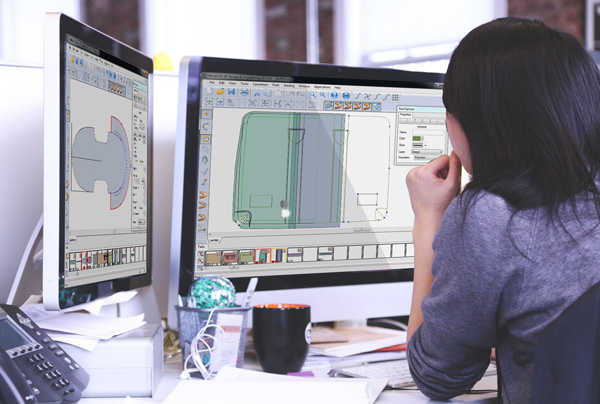

MindCAD

Product design & engineering

Speed and efficiency

Meet your time-to-market goals; respond quickly to changing trends and fast fashion on luggage and bags.

Be faster and more productive in developing new models.

Reuse developed models to create new series.

Reuse parts and cutters across models, reducing costs and production times.

Flexibility

Easily change your industrial plans, with immediate results in patterns and sizes.

Execute parameterized sizing, applied to groups or parts of pieces.

Reuse and reduce required cutters.

Precision

Set margins and overlaps with high precision, optimizing material consumption.

Automatically place markers, corners, edges, and notches.

Tightly control measures.

2D features for Leather Goods

-

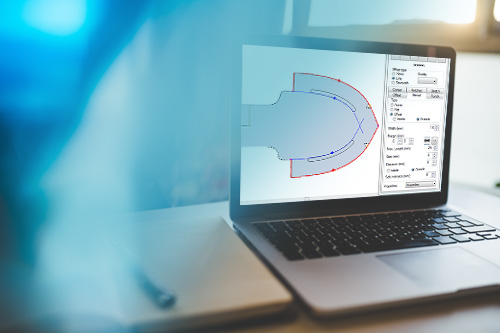

Patterns digitizing

Interactive data input using a 2D digitizing tablet (in continuous or point by point modes).

Automatic digitizing of parts using a flatbed scanner.

Support for multiple digitizing scanners, including large format scanners.

-

2D modeling tools

Definition of style lines.

Related and unrelated lines.

Measurement tools.

Interactive and automatic tools for line distortion.

-

Creating patterns

Complete pattern definition without adding auxiliary lines.

Definition of dependencies between disconnected parts, ensuring stitching continuity.

Automatic definition of margins, overlaps, and others.

Automatic creation of notches, fillets, drills, and stencils.

-

Integration

Tight integration with MindCUT software for automatic nesting and cutting.

Full integration and data exchange with MindGEST PDM, a centralized information repository for products and processes.

Interoperability with MindGEST Cost Evaluation for cost assessment based on product engineering options and production scenarios.