Streamline your product development with our standalone marking system.

Achieve greater benefits for your industry with MindCUT DIVA

Enhanced productivity

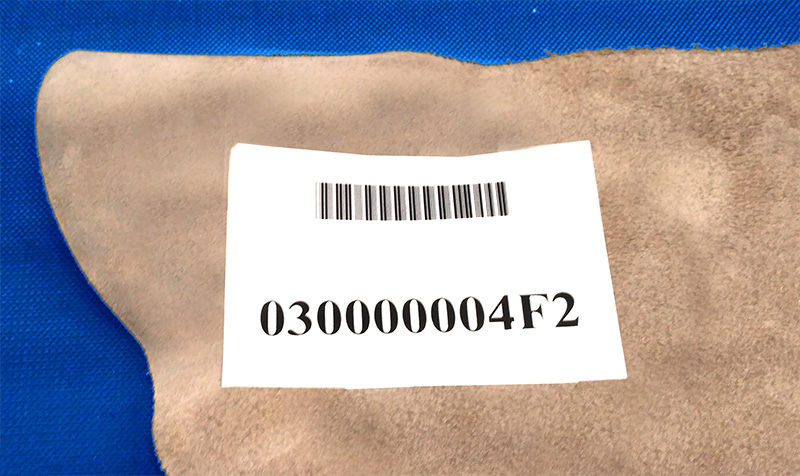

The continuous “conveyor feed and capture” process, combining the defects marking and the automatic identification of leather boundaries, enhances operator productivity and overcomes material length limitations.

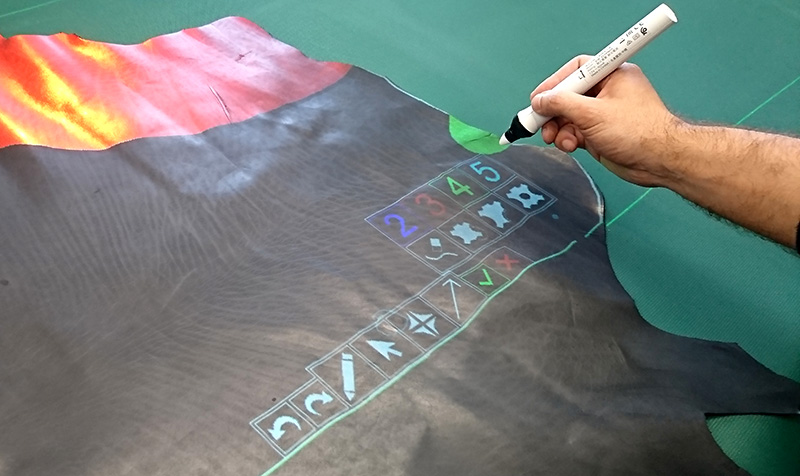

Innovative marking

MindCUT’s non-physical, non-destructive digital marking process preserves the high quality of the leather materials. The real-time marking guarantees a quick and accurate classification process.

Streamlined production

Meet your customers’ demand for high-volume processing with an integrated offline production environment.

Precision and ease of use

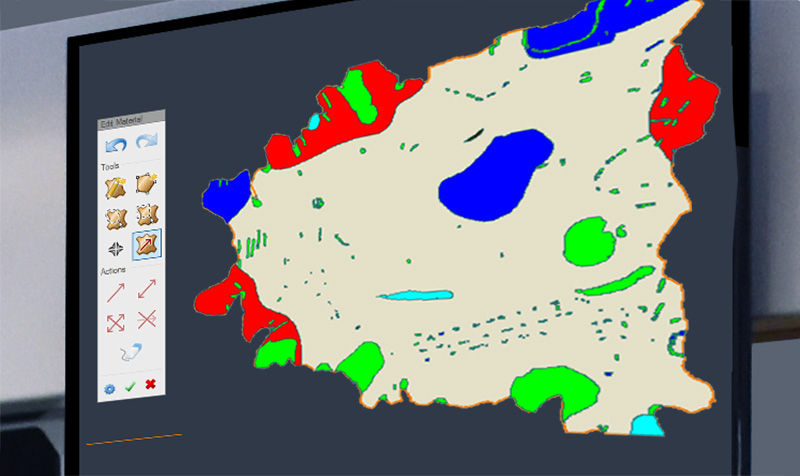

The MindCUT Digitizer simplifies the marking, capture, and classification process, and makes production precise yet simple. Our machine offers innovative digital pen marking, high resolution image capture, and real-time projected information.

The contour, holes, and quality areas of your leather are easily recognized and classifiable.

Integrated environment

MindCUT Digitizer is compatible with MindCUT Automatic Nesting and Cut Systems, ensuring integrated process management and the best performance.