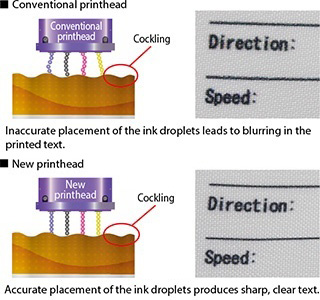

The new high-gap printhead achieves high-quality printing on cockled transfer papers.

Low-cost thin transfer papers are liable to cockling*, which affects the quality of the printhead. To prevent the contact between the printhead and raised surface, a high head gap setting is required. In conventional models, such gap conditions reduce the accuracy of the ink droplet placement. The new TS300P-1800 employs a new printhead that ensures accurate ink droplet placement with a high head gap, thereby enabling high-quality printing on thin papers.

* Cockling: Wrinkling of the media surface because of ink absorption.

Cockling-reduction transfer mechanism

The cockling-reduction transfer mechanism enables high-quality printing on a wide range of transfer papers, from the low-cost thick papers. This high media compatibility reduces the operating cost of the TS300P-1800 without losing the print quality.

① Vacuum media hold-down system beneath the platen

The media attach to the platen by vacuum suction. Under suction, the cockled media surfaces are smoothed out.

② Larger media press plates

Enlarged plates moderate cockling by reducing media uplift and hold down the media immediately after printing.

③ Auto Media Feeder (AMF)

The AMF automatically applies the right tension to the media, thereby maintaining stable media feeding and take-up.

Conventional vs New printhead

Conventional vs New printhead

Cockling-reduction transfer mechanism

Cockling-reduction transfer mechanism